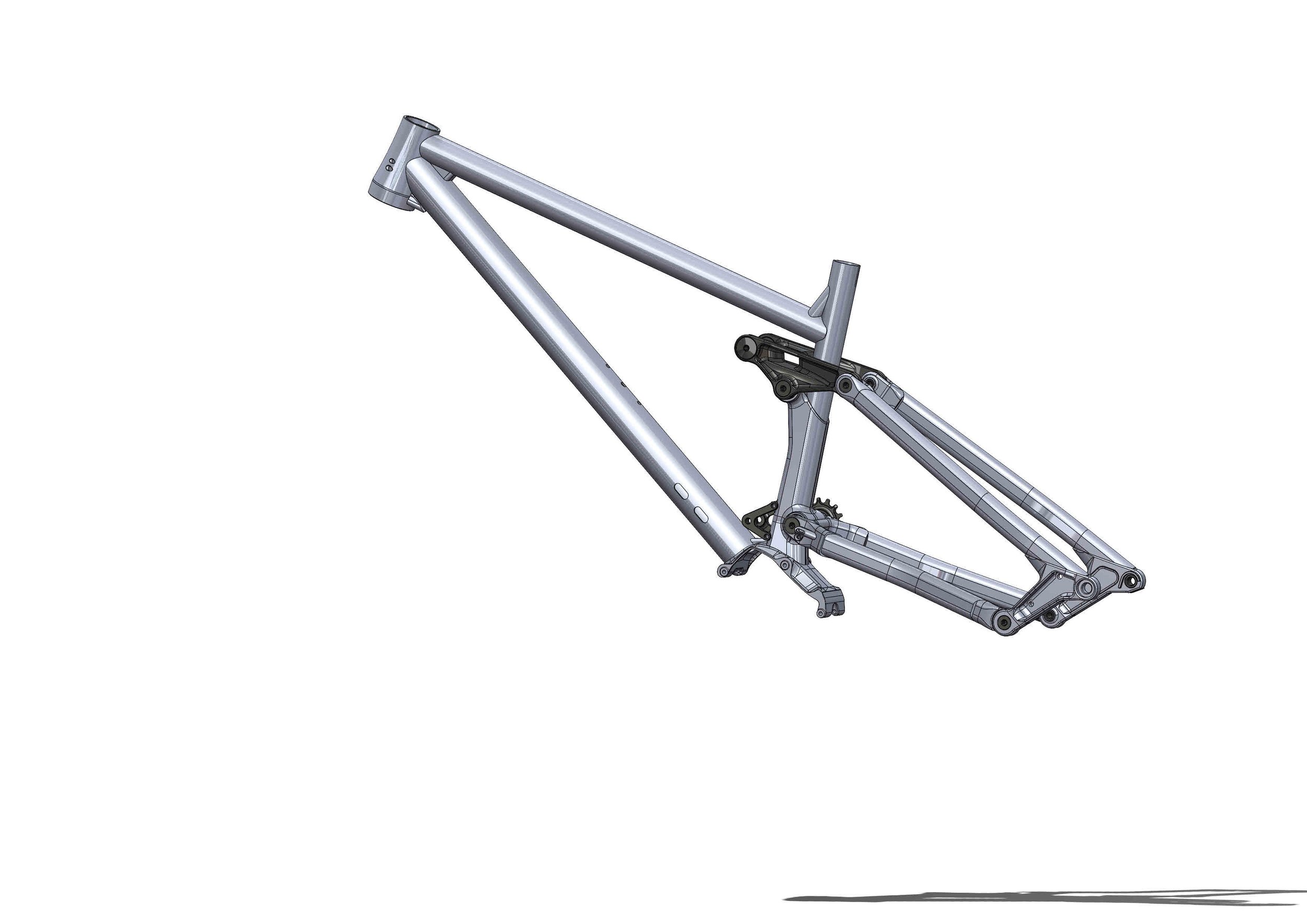

Kavenz gearbox prototype

At Kavenz, we love creating unique bikes and prototypes just for fun. We've received countless requests for a VHP gearbox frame and decided to rise to the challenge. Our team had no prior experience with gearbox bikes, so we were thrilled to build one and share our journey with you.

The Prototype

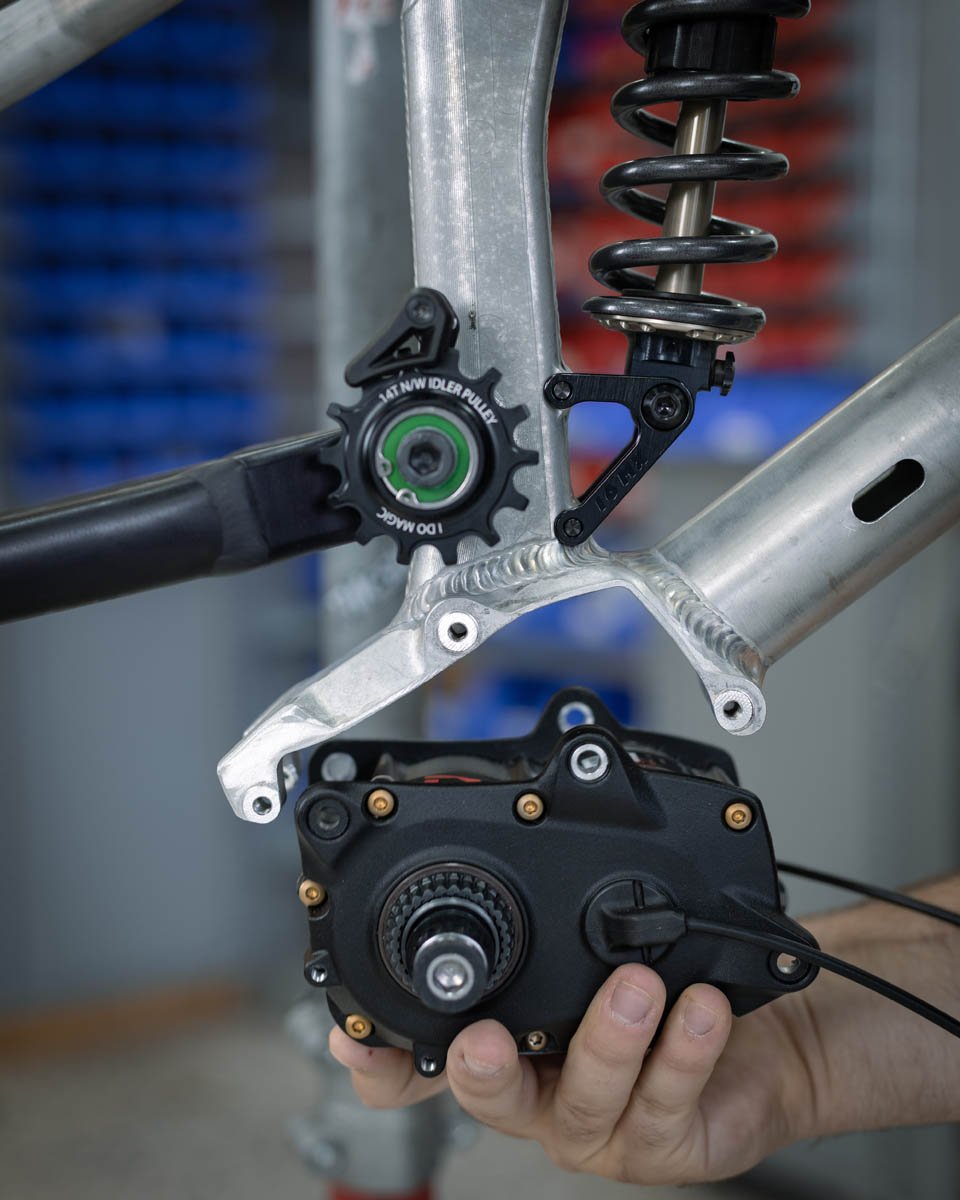

The easiest way to make a gearbox prototype from a regular frame was to use a standard weld-on gearbox mounting plate from Pinion, initially designed for hardtails. There was little clearance on the rear wheel, so we had to cut some elements by hand. Then we used an angle grinder to make everything smoother. We also had to drill some holes for the dropper post cable, which you can see on our Instagram, where we posted many behind-the-scenes updates.

Testing

We build two GWAGONs for testing. One was made for our team, and the second went to Yannick Lange from Trickstuff, who initially pushed this product to live. Our bike has Effigear on board, while Yannick uses a gearbox from Pinion. So we could test both systems.

General Observation:

Super fast and planted due to the central and low mass of the bike and the low unsprung weight.

We need to use a different chain tensioner for the final version. I repeatedly hit the ground, roots, or rocks with the tensioner.

The gear ratio is pretty big; you can climb well and fast on the flat road.

Legs feel stable on the pedals when going downhill. Since the chain continues rotating, it does not affect the cranks.

Effigear:

Shifting into harder gears is incredibly smooth, regardless of how bumpy and rough the trails are. Shifting up requires unweighting the pedal, which takes time to get used to.

Pinion:

The grip shift is rather tricky to use for enduro applications.

For the first serial production, we fixed the following details.

-The Dropper Post Cable is now routed internally.

-The Effigear Spring can be accommodated in the Down-tube and be fixed to avoid rattling.

-We will add a slider for the rear sprocket to keep the chain where it belongs

Chain Tensioner

We also started to work on our solution for the chain tensioner, but it´s not that easy to do as the chain has to cross the chain stays. Our idea is to add a slider element behind the horst link that routes the chain around the chain stay when fully extended and also functions as a guide for the sprocket. Effigear is also still working on something, and the chain tensioner from Pinion is already working pretty well. If we receive enough pre-orders, we will make a big push in R&D and finish our solution in time for the rollout of the initial batch.

How can I ORDER One?

Batch 1 of VHP G frames is currently in the making. We will inform you if we will be open for a batch 2. Currently it’s not possible to order VHP